How To

How do I manage inventory for child products?

Follow these steps

A child product is a variation of a product that stems from a parent product. Most often, the variation is in the number of units sold as one unit. The parent product is the original form of the product, and the child product is the subsequent product of the parent product with the variation.

When managing child product inventory, we recommend the following tips.

Setting a product minimum on the parent product

Consider the number of child products you're selling when setting the minimum desired quantity for the parent product. If you you GlobalTill's automated PO generation, this ensures your ordering enough for both the child and the parent product.

To set a minimum desired quantity on the parent product, follow these steps.

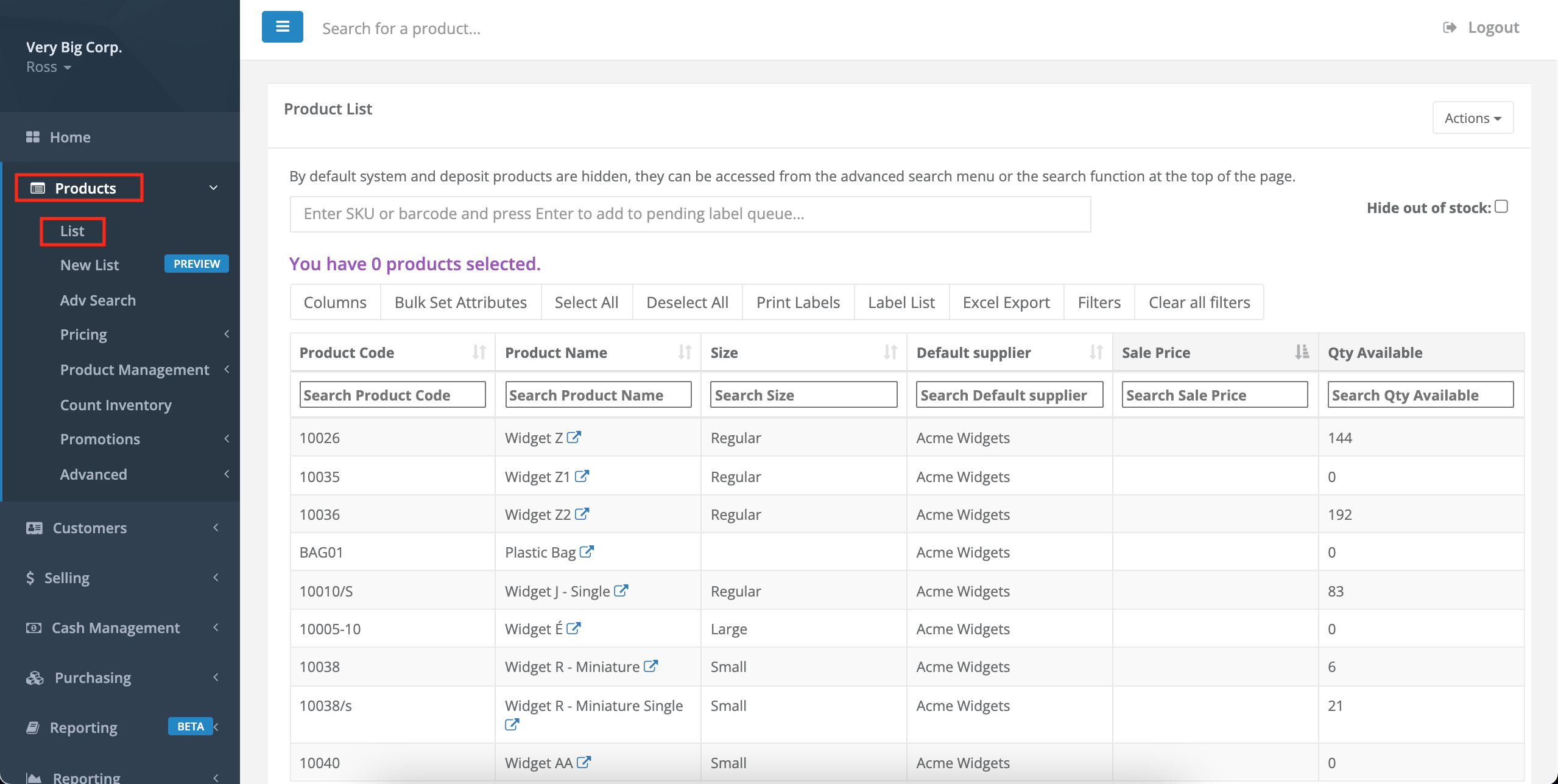

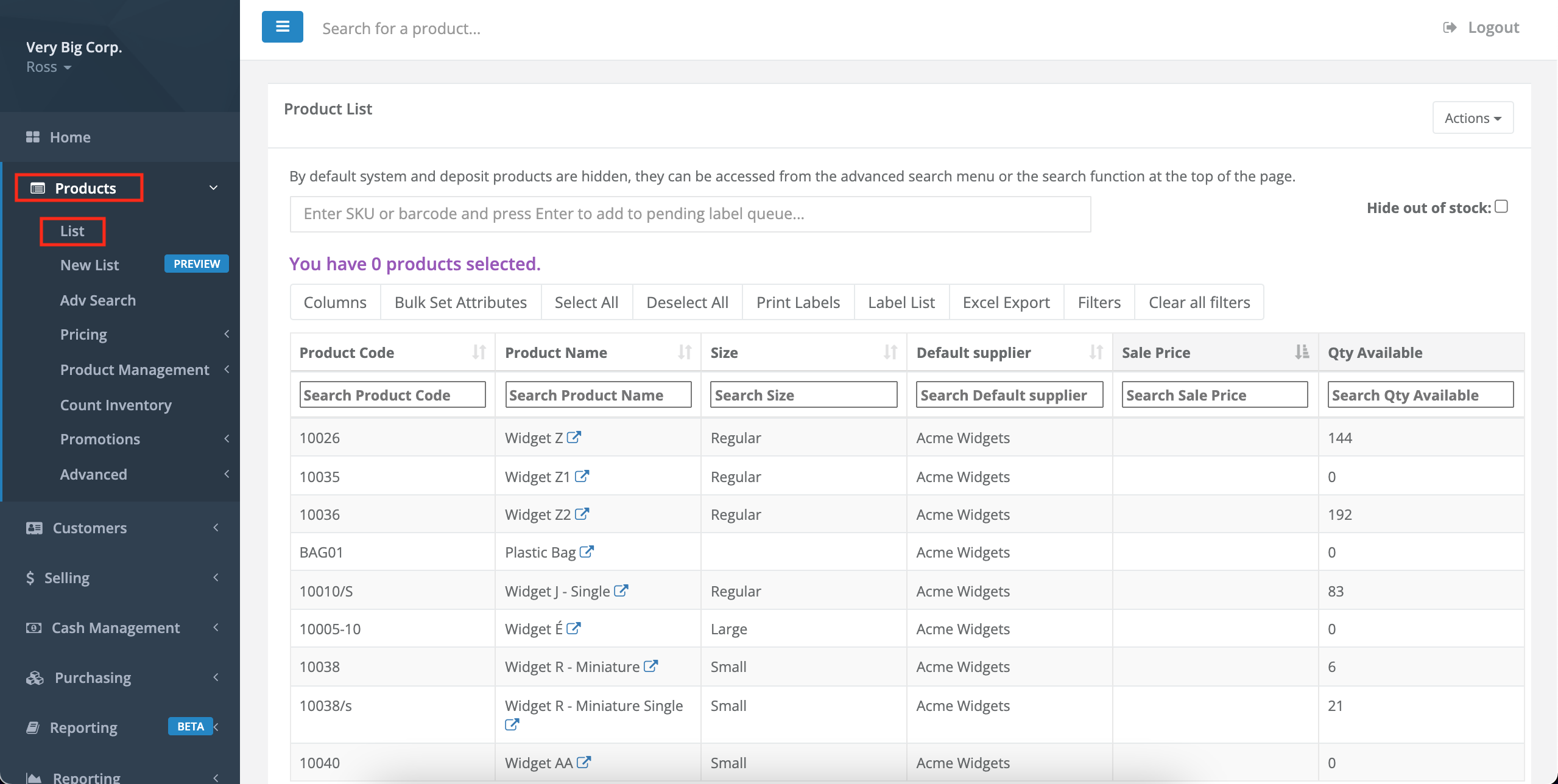

- Select Products > List.

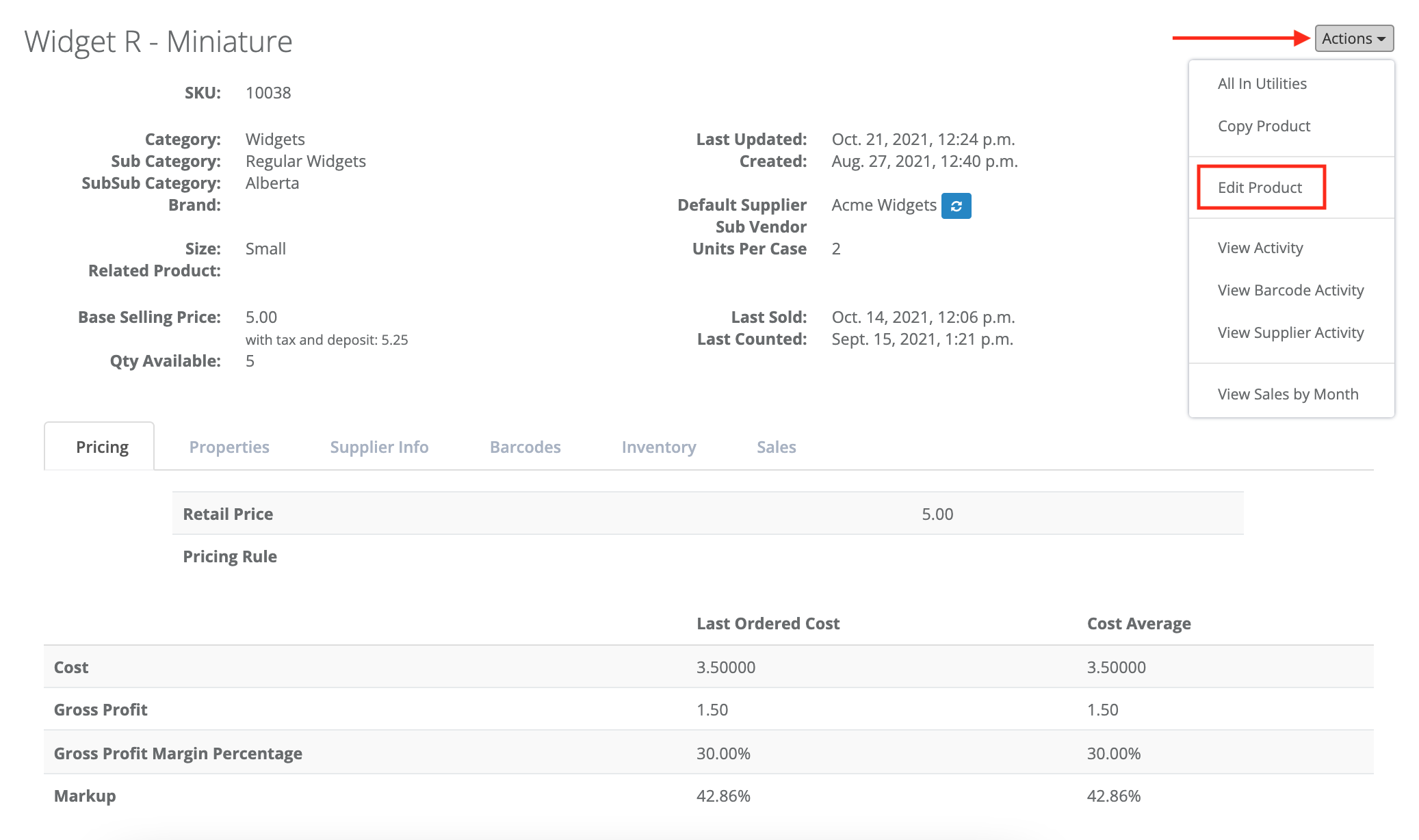

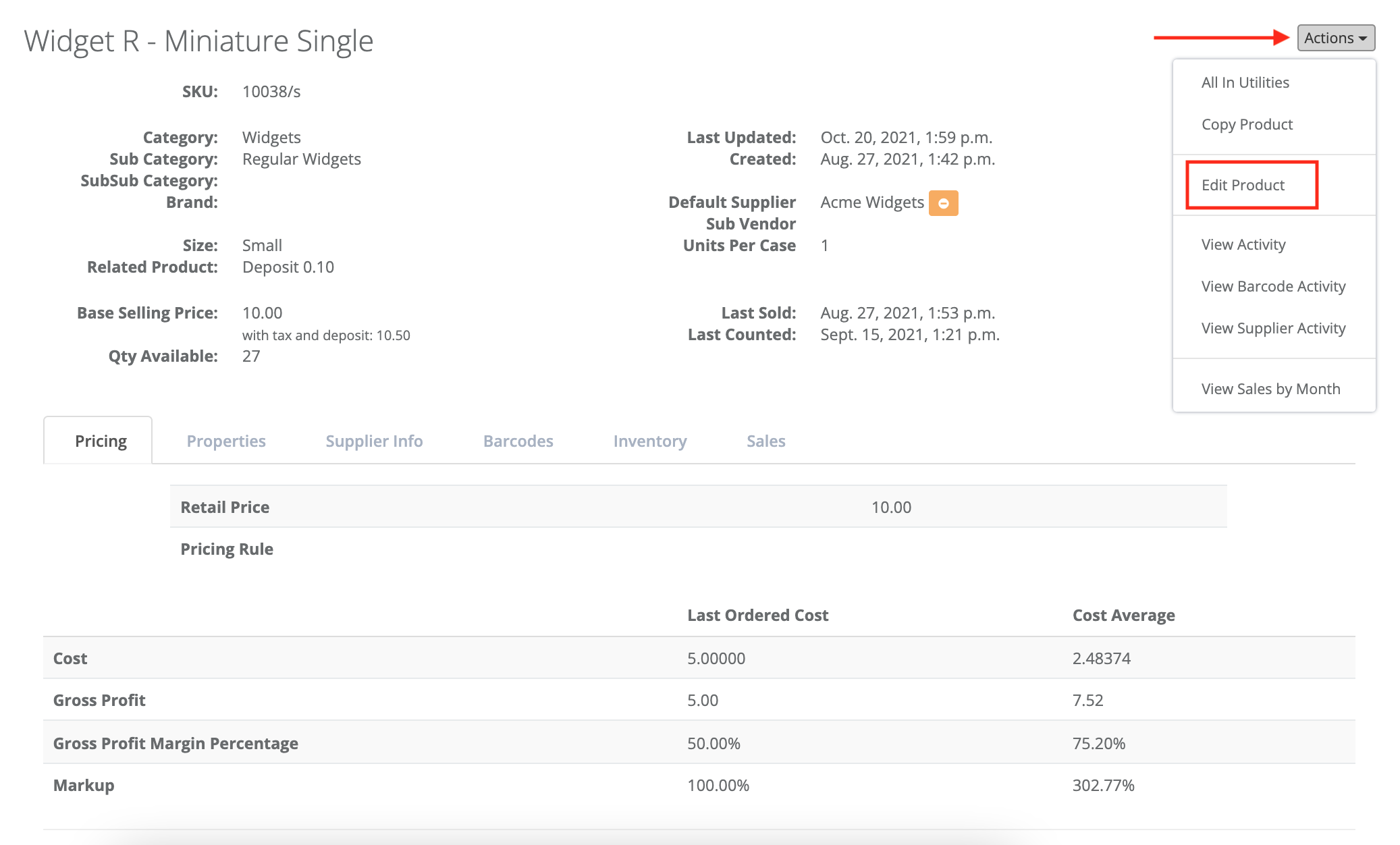

- Search for and select the parent product then select Actions > Edit Product.

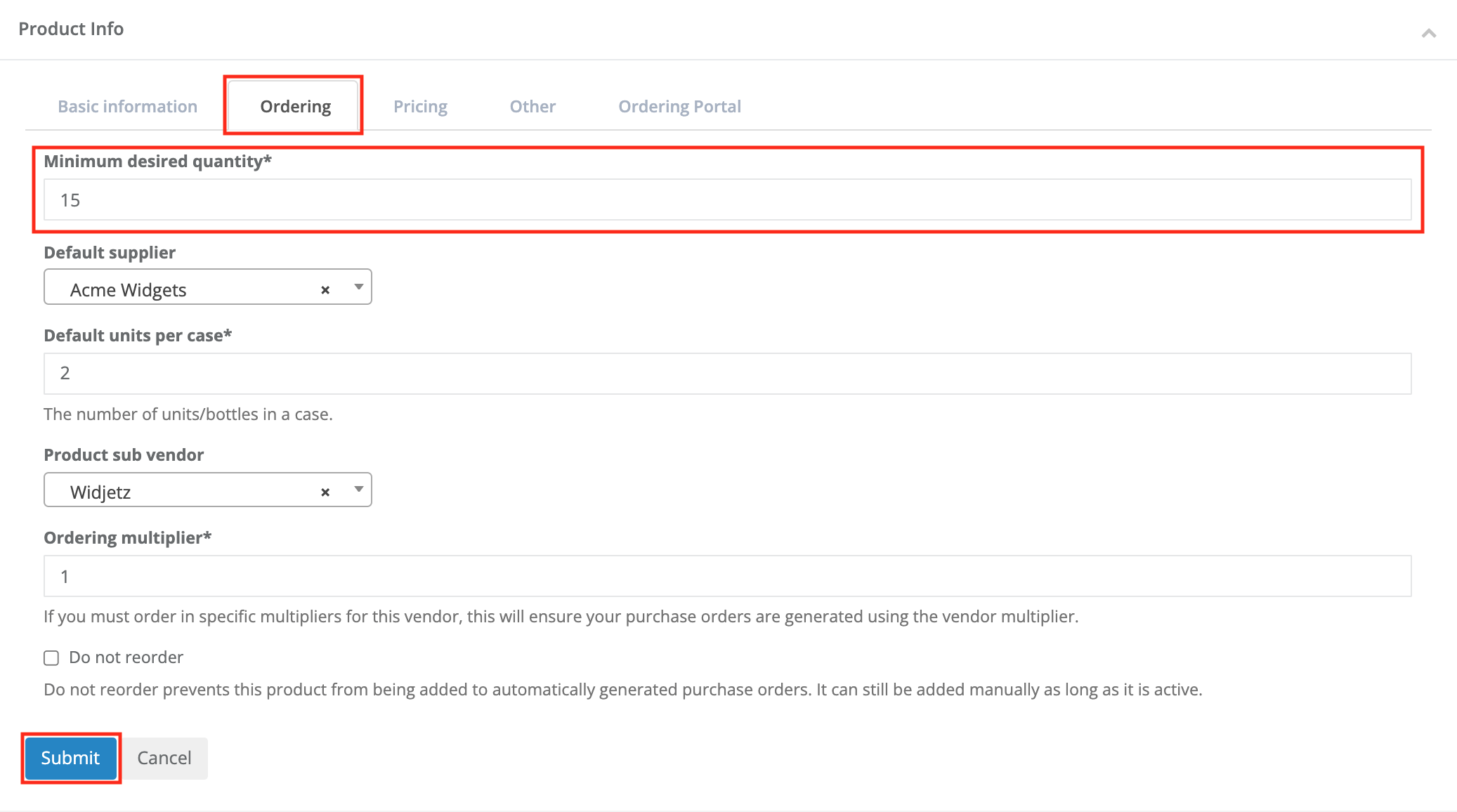

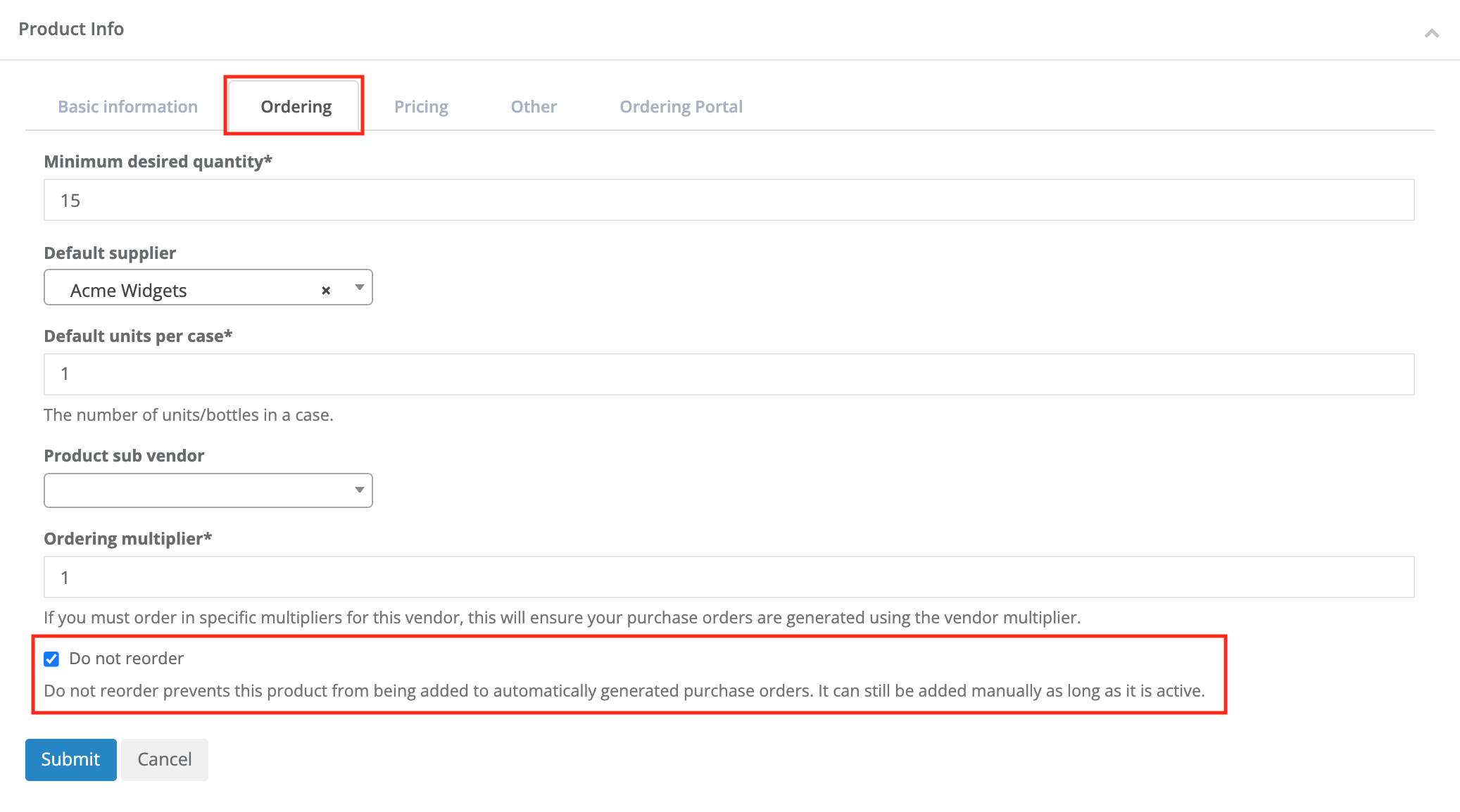

- Select the Ordering tab.

- Enter a Minimum desired quantity, then select Submit.

Enable do not reorder on child product

Because the child product is created by you in your store, and not purchased directly from a supplier, we recommend you enable Do Not Reorder on the child product's ordering tab. This is to prevent the modified SKU from being added to auto-generated POs.

To enable do not reorder on the child product, follow these steps.

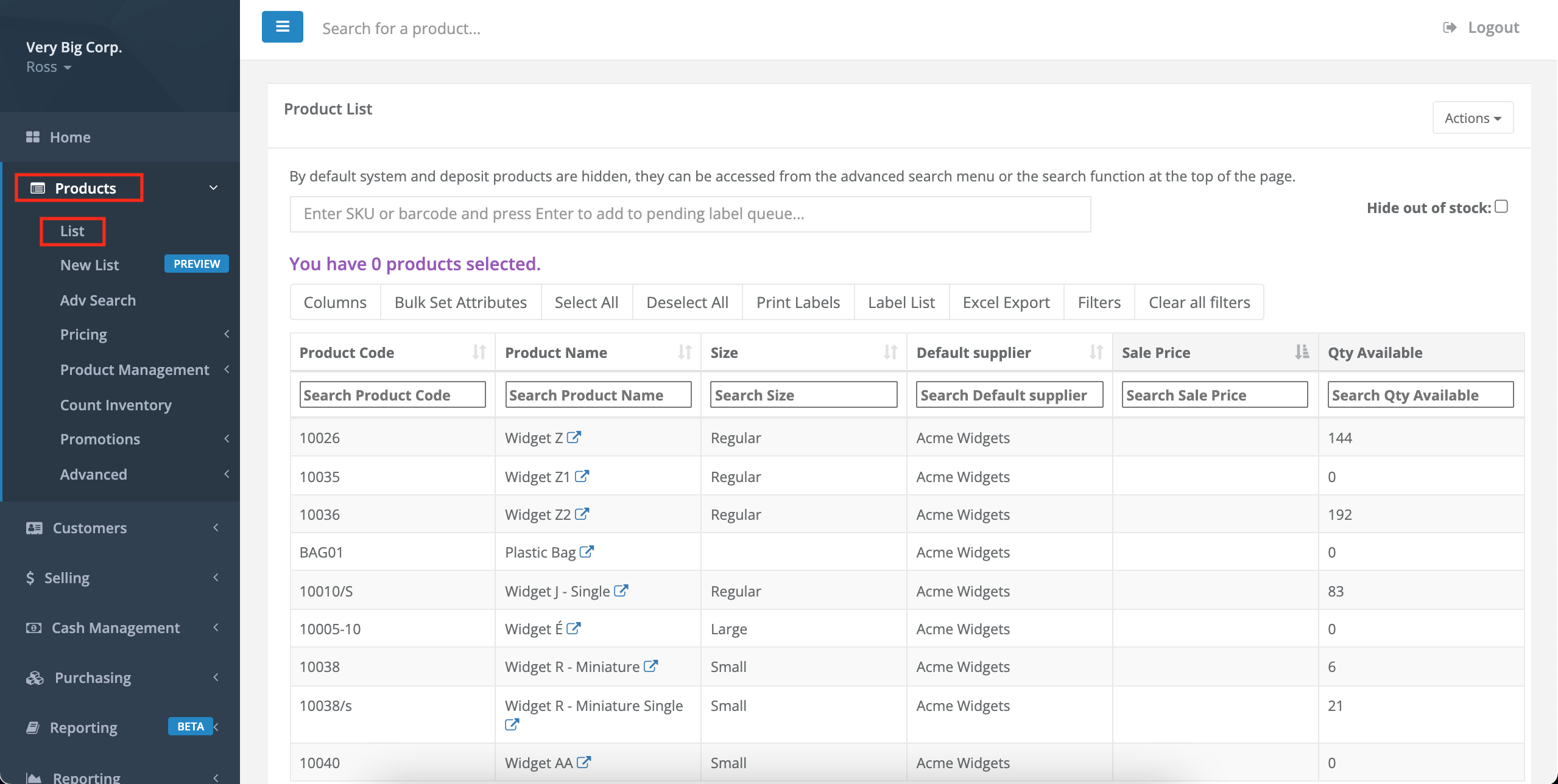

- Select Products > List.

- Search for and select the child product, then select Actions > Edit Product.

- Select the Ordering tab.

- Check Do not reorder, then select Submit.

Use repackage to balance and eliminate negative quantities on child products

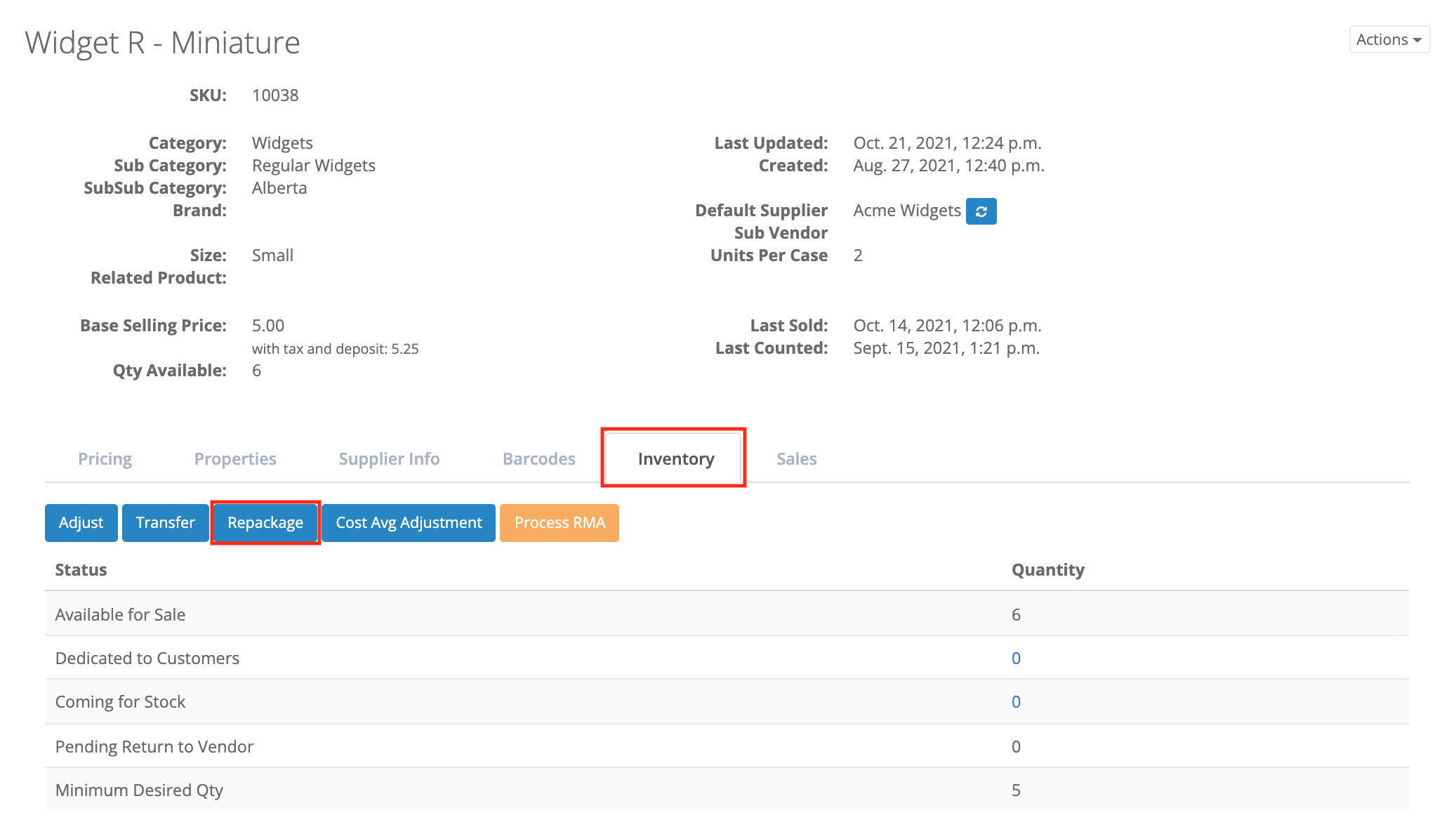

Creating a child product covers the physical sale of product variations, however, we recommend using the Repackage function when working with child products to ensure inventory is tracked accurately.

For example, if you sell six single cans of beer as child products that were originally packaged as a 6-pack, the child product SKU would show an inventory of -6 units.

To account for the -6 units, you could repackage one 6-pack with an output quantity of six single cans.

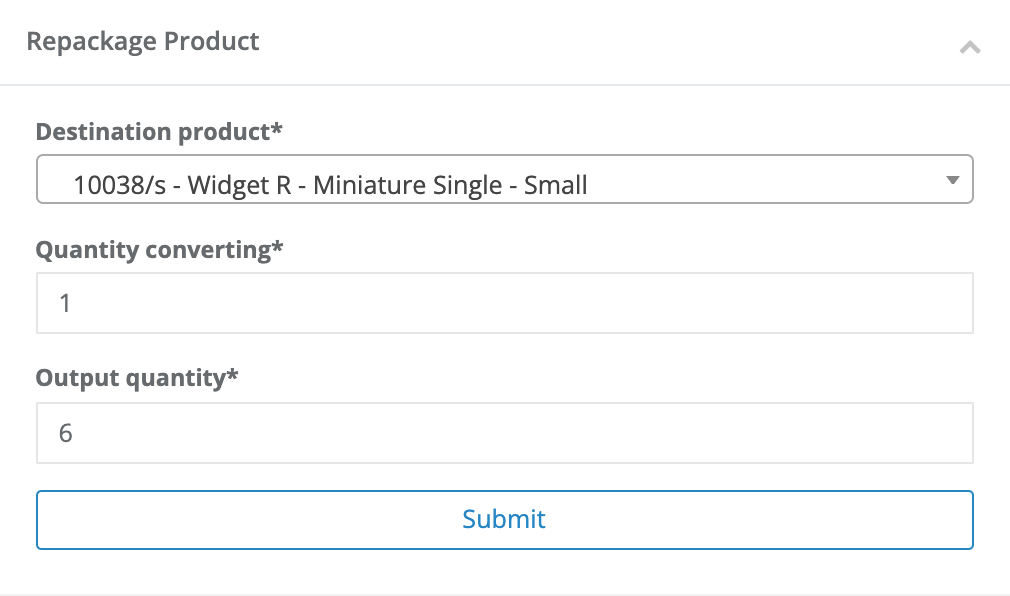

To adjust the inventory by repackaging, follow these steps.

- Select Products > List.

- Search for and select the parent product.

- Select the Inventory tab.

- Select Repackage.

- Enter the child product as the Destination product.

- Enter the number of parent products you are converting into child products as the Quantity converting.

- Enter the resulting number of child products created as the Output quantity, then select Submit.

More Information

For more information about child products, see the article How to use a child product.

Comments

Please sign in to leave a comment.